Features

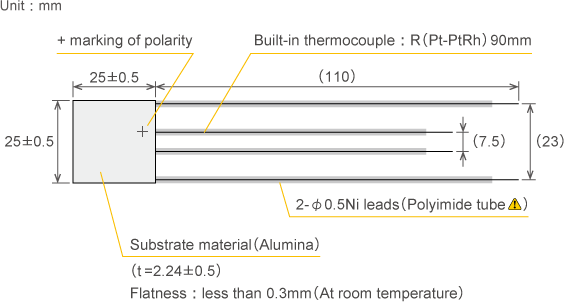

- R type thermocouple incorporated in the heater substrate material.

- More precise controllability for your operation.

Specification

All products listed are available in different voltages.

Please replace polyimide tube with ceramic tube in case high temperature operation due to the heat resistant temperature of polyimide tube is 300℃.

| Voltage(AC) | 100 V |

|---|---|

| Wattage | 555 W ± 25%(At room temperature) |

| Watt density | 89 W/cm2(At room temperature) |

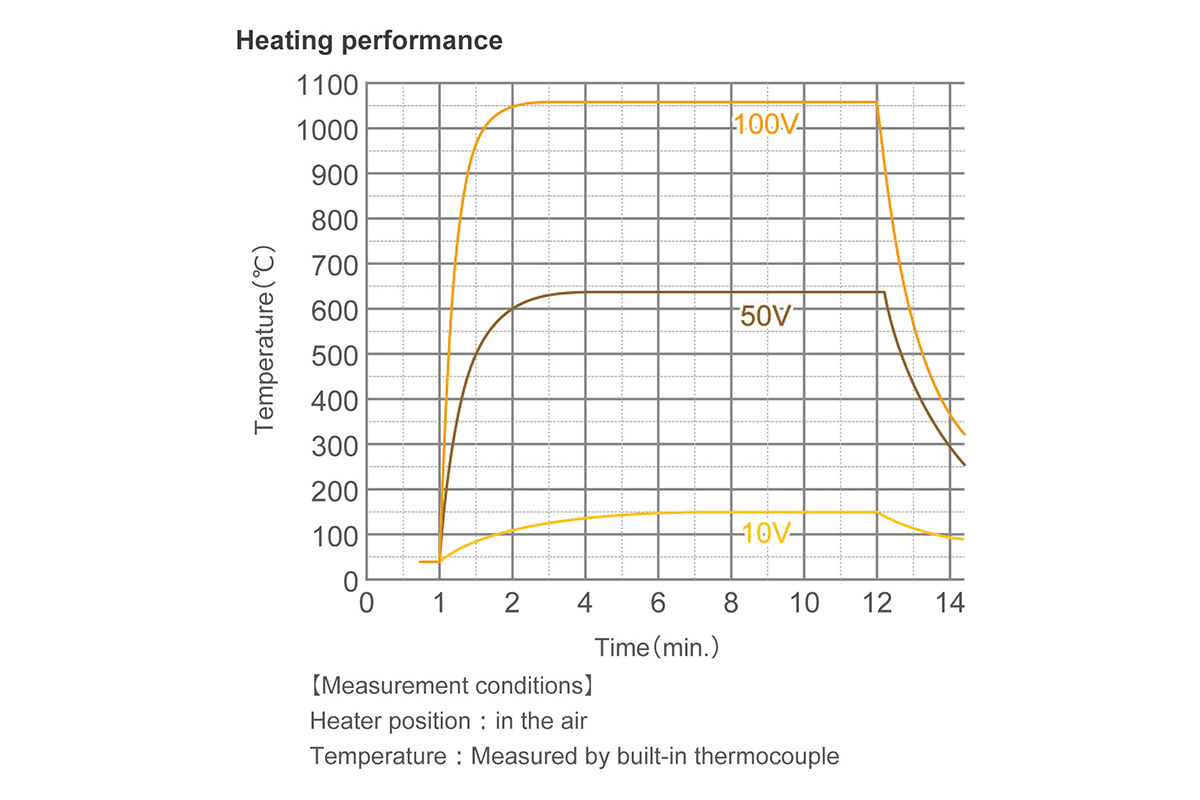

| Operating temperature | 1000℃(Built-in thermocouple) |

| Thermocouple | R φ0.3(Pt-PtRh13%) |

| Accessories | Ceramic tube(φ1.2×φ0.8×5L) |

| Product code | MS-1000R |

*Operating temperature must be carefully controlled by built-in thermocouple due to high watt density.

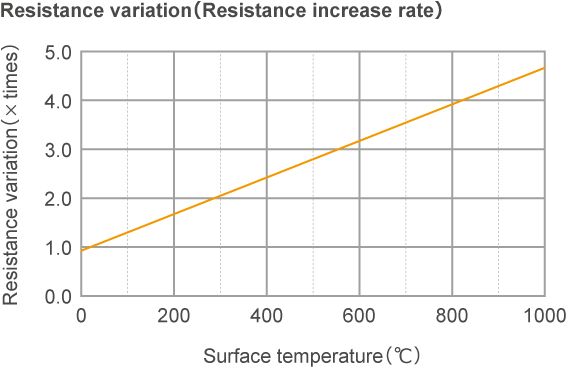

*Above mentioned wattage is measured at normal temperature conditions. The value will change along with the increase of temperature. Refer to below chart of resistance variation.

*Thermoelectromotive of built-in thermocouple is as per JIS C 1602.

Reference data

Precautions for use

- For thermal insulation and shock absorbing purpose, some cushioning material such as ceramic paper is recommended to use when the whole of heater body is covered with heated material while operation.

Otherwise, there is a case that the heater might be cracked and/or broken due to thermal expansion of heated material. - Heating up and Cooling down

Though the heaters are capable of rapid heating up and rapid cooling down, gradual fluctuation of operating temperature is recommendable.

(Recommend:ramping up 100℃ in one minute and cooling down 200℃ in one minute or more) - CAUTION in colder conditions

When heating up the heater under lower temperature than ambient, the heater resistance is decreasing and watt density will became higher.

This may cause breaking of the heater when applying rated voltages.

To prevent this kinds of accident, we recommend to start up from lower voltages by using transformer and increase the voltage gradually. - Thermal shock resistance temperature of substrate material is approximately 200℃.

- AC (Alternating Current) to be applied to the heater.

- Optional:Temperature controller model No. "SCR-SHQ-A2" for optimum control.

![[Built-in thermocouple] MICRO CERAMIC HEATER series "MS-1000R"](img/001.jpg)