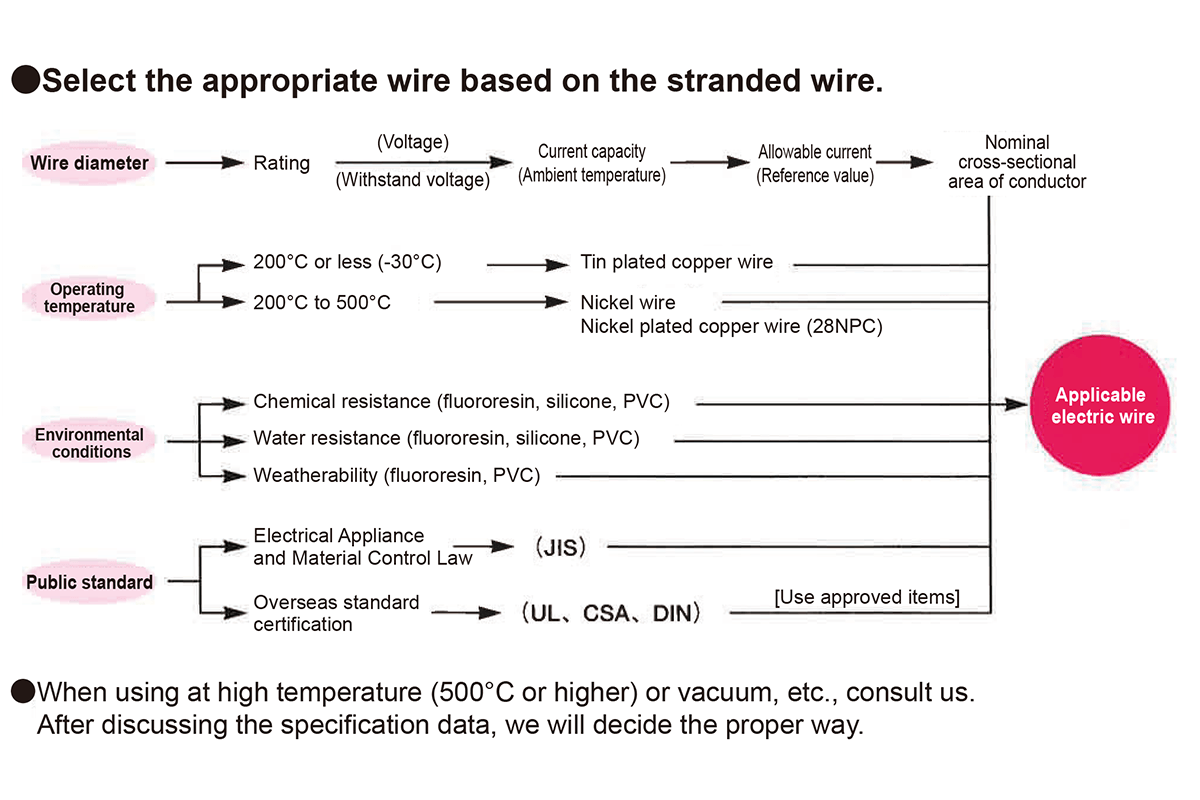

How to select electric wires (approximate)

For the heater lead wires and electric wires used for electric heating equipment,etc., those compliant with the ratings used, operating temperature, and publicstandard certification should be selected.

We provide a large number of compatible electric wires corresponding to various Normal product fields.

Note on terminal processing of heat-resistant electric wire

When connecting the heat-resistant wire to the heater or the terminal of equipment, perform terminal treatment of the heat-resistant wire using a proper crimp terminal, etc. and secure it completelywith screws or welding, etc.

Particularly when using it in a high-temperature atmosphere, be careful that the contact resistance increases due to oxidation of the surface of the contact part, causing abnormal heat generation and leading to damage to the equipment or fire.

Specification

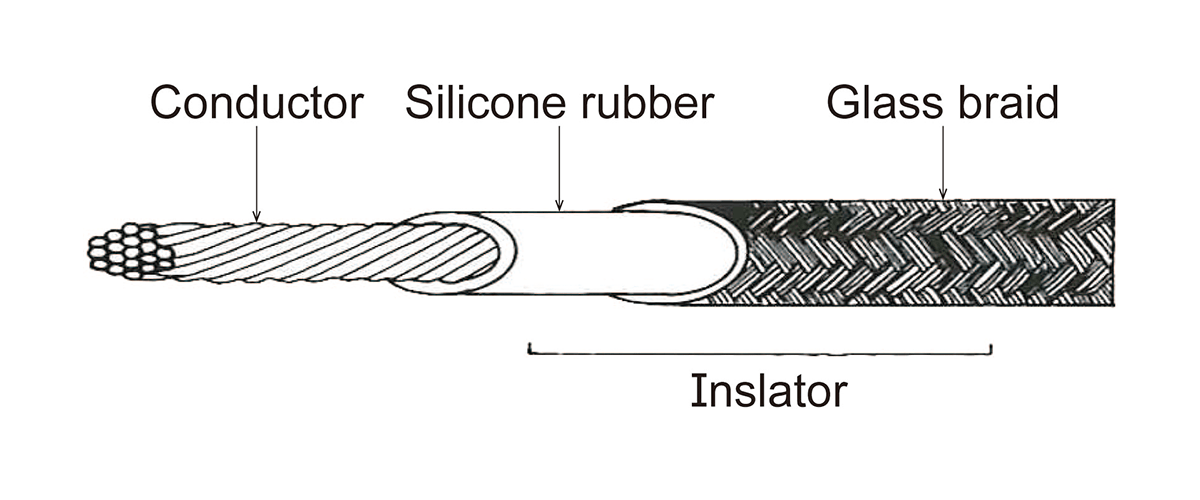

GG wire

External view

Specifications

| Conductor | Tin plated copper wire |

|---|---|

| Insulator | Silicone rubber Glass single braid |

| Safe operating temperature | 180°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Insulator thickness | Braid thickness | Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||||

| 0.5mm2 | 20/0.18mm | 0.9mm | 0.3mm | 0.2mm | 1.9mm | 38.6Ω/km | 100MΩ/km | 1500V/min | 4A |

| 0.75mm2 | 30/0.18mm | 1.1mm | 0.4mm | 0.2mm | 2.4mm | 25.8Ω/km | 100MΩ/km | 1500V/min | 8A |

| 1.25mm2 | 50/0.18mm | 2.5mm | 0.4mm | 0.2mm | 2.7mm | 15.5Ω/km | 100MΩ/km | 1500V/min | 11A |

| 2mm2 | 37/0.26mm | 1.8mm | 0.5mm | 0.2mm | 3.2mm | 9.91Ω/km | 100MΩ/km | 1500V/min | 14A |

| 3.5mm2 | 45/0.32mm | 2.5mm | 0.6mm | 0.25mm | 4.2mm | 5.38Ω/km | 100MΩ/km | 1500V/min | 21A |

| 5.5mm2 | 35/0.45mm | 3.1mm | 0.6mm | 0.25mm | 4.8mm | 3.46Ω/km | 90MΩ/km | 1500V/min | 28A |

| 8mm2 | 50/0.45mm | 3.7mm | 0.8mm | 0.25mm | 5.8mm | 2.45Ω/km | 80MΩ/km | 1500V/min | 42A |

The allowable current is a reference value of tin-plated soft copper wire (up to 150°C). It varies depending on the operating conditions.

For details, contact our sales representative.

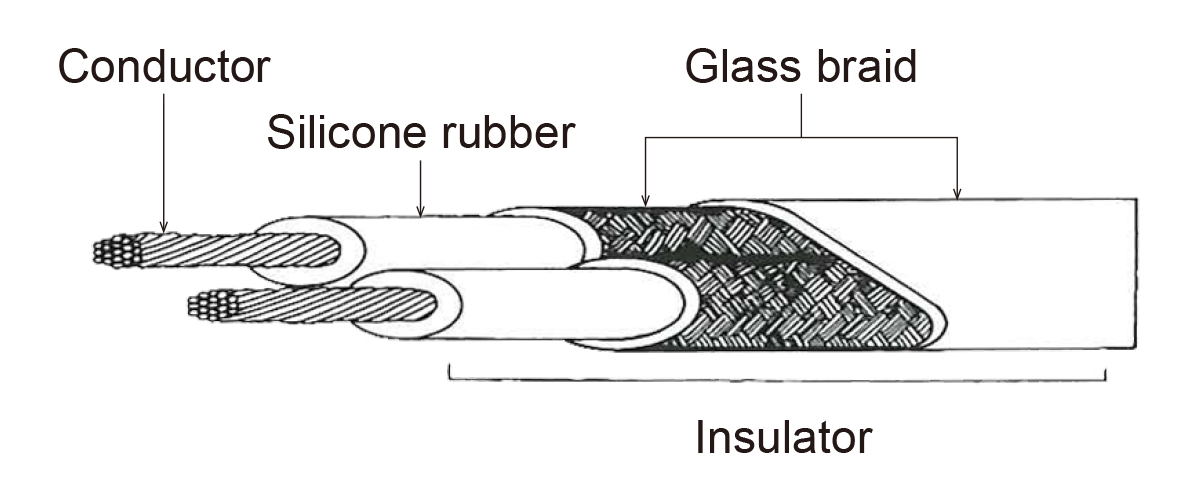

GG wire(2-core type)

External view

Specifications

| Conductor | Tin plated copper wire |

|---|---|

| Insulator | Silicone rubber Glass single braid Parallel single braid |

| Safe operating temperature | 180°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Insulator thickness | Braid thickness | Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||||

| 0.75mm2 | 30/0.18mm | 1.1mm | 0.4mm | 0.25mm | 3.1×4.9mm | 25.8Ω/km | 100MΩ/km | 1500V/min | 5A |

| 1.25mm2 | 50/0.18mm | 1.5mm | 0.4mm | 0.25mm | 3.5×5.8mm | 15.5Ω/km | 100MΩ/km | 1500V/min | 7A |

| 2mm2 | 37/0.26mm | 1.8mm | 0.5mm | 0.3mm | 4.3×7.0mm | 9.91Ω/km | 100MΩ/km | 1500V/min | 9A |

The allowable current is a reference value of tin-plated soft copper wire (up to 150°C). It varies depending on the operating conditions.

For details, contact our sales representative.

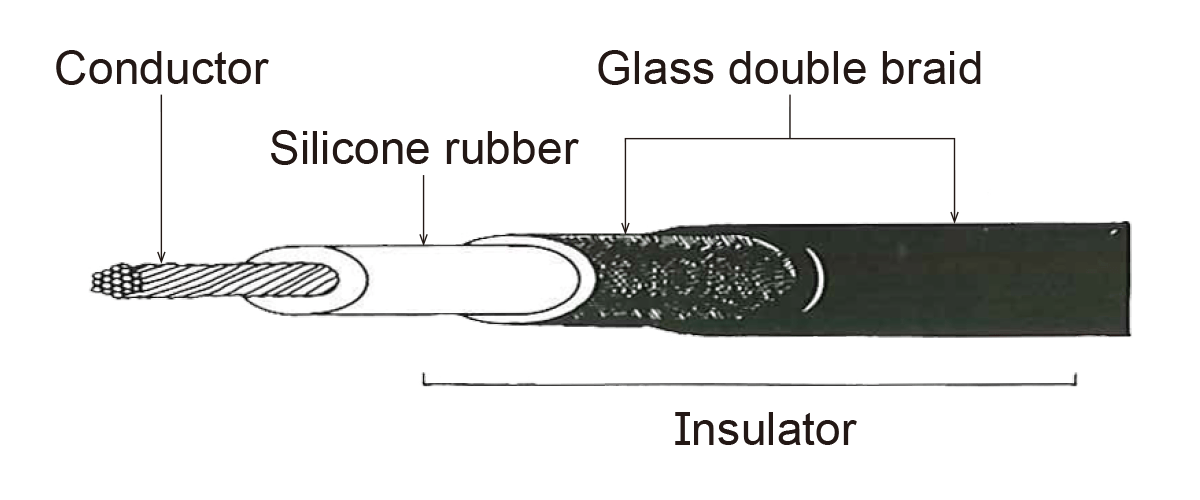

LKGB wire

External view

Specifications

| Conductor | Tin plated copper wire |

|---|---|

| Insulator | Silicone rubber Glass double braid |

| Safe operating temperature | 180°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Insulator thickness | Braid thickness | Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||||

| 0.75mm2 | 30/0.18mm | 1.1mm | 1.1mm | 0.5mm | 4.3mm | 25.8Ω/km | 100MΩ/km | 1500V/min | 8A |

| 1.25mm2 | 50/0.18mm | 1.5mm | 1.1mm | 0.5mm | 4.7mm | 15.5Ω/km | 100MΩ/km | 1500V/min | 11A |

| 2mm2 | 37/0.26mm | 1.8mm | 1.1mm | 0.5mm | 5mm | 9.91Ω/km | 100MΩ/km | 1500V/min | 14A |

| 3.5mm2 | 45/0.32mm | 2.5mm | 1.1mm | 0.5mm | 5.7mm | 5.38Ω/km | 100MΩ/km | 1500V/min | 21A |

| 5.5mm2 | 35/0.45mm | 3.1mm | 1.1mm | 0.5mm | 6.3mm | 3.46Ω/km | 90MΩ/km | 1500V/min | 28A |

| 8mm2 | 50/0.45mm | 3.7mm | 1.1mm | 0.5mm | 6.9mm | 2.45Ω/km | 80MΩ/km | 1500V/min | 42A |

| *14.0mm2 | 88/0.45mm | 4.9mm | 1.1mm | 0.6mm | 8.3mm | 1.39Ω/km | 60MΩ/km | 2000V/min | 63A |

| *22.0mm2 | 7/20/0.45mm | 7mm | 1.4mm | 0.6mm | 11mm | 0.892Ω/km | 60MΩ/km | 2000V/min | 85A |

| *30.0mm2 | 7/27/0.45mm | 8.1mm | 1.4mm | 0.6mm | 12.1mm | 0.661Ω/km | 60MΩ/km | 2000V/min | 139A |

| *38.0mm2 | 7/34/0.45mm | 9.1mm | 1.4mm | 0.6mm | 13.1mm | 0.525Ω/km | 50MΩ/km | 2500V/min | 162A |

The allowable current is a reference value of tin-plated soft copper wire (up to 150°C). It varies depending on the operating conditions.

For details, contact our sales representative.

* is made to order. For the minimum lot, etc., contact our sales representative.

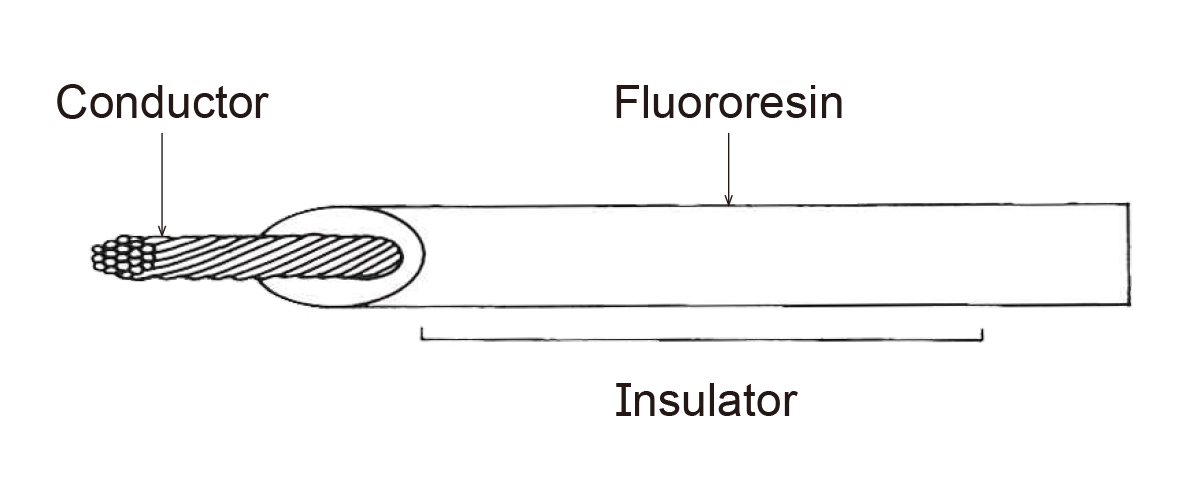

Fluororesin electric wire

External view

Specifications

| Conductor | Tin plated copper wire |

|---|---|

| Insulator | FEP-6F |

| Safe operating temperature | 200°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Insulator thickness | Braid thickness | Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||||

| 0.5mm2 | 19/0.18mm | 0.9mm | 0.25mm | –mm | 1.4mm | 40.6Ω/km | 1500MΩ/km | 2000V/min | 4A |

| 0.75mm2 | 30/0.18mm | 1.15mm | 0.3mm | –mm | 1.75mm | 25.8Ω/km | 1500MΩ/km | 2000V/min | 8A |

| 1.25mm2 | 50/0.18mm | 1.48mm | 0.3mm | –mm | 2.08mm | 15.5Ω/km | 1500MΩ/km | 2000V/min | 11A |

| 2mm2 | 37/0.26mm | 1.8mm | 0.3mm | –mm | 2.4mm | 9.91Ω/km | 1500MΩ/km | 2000V/min | 14A |

| 3.5mm2 | 45/0.32mm | 2.5mm | 0.3mm | –mm | 3.1mm | 5.37Ω/km | 1500MΩ/km | 2000V/min | 21A |

| 5.5mm2 | 35/0.45mm | 3.1mm | 0.3mm | –mm | 3.7mm | 3.5Ω/km | 1500MΩ/km | 2000V/min | 28A |

The allowable current is a reference value of tin-plated soft copper wire (up to 150°C). It varies depending on the operating conditions.

For details, contact our sales representative.

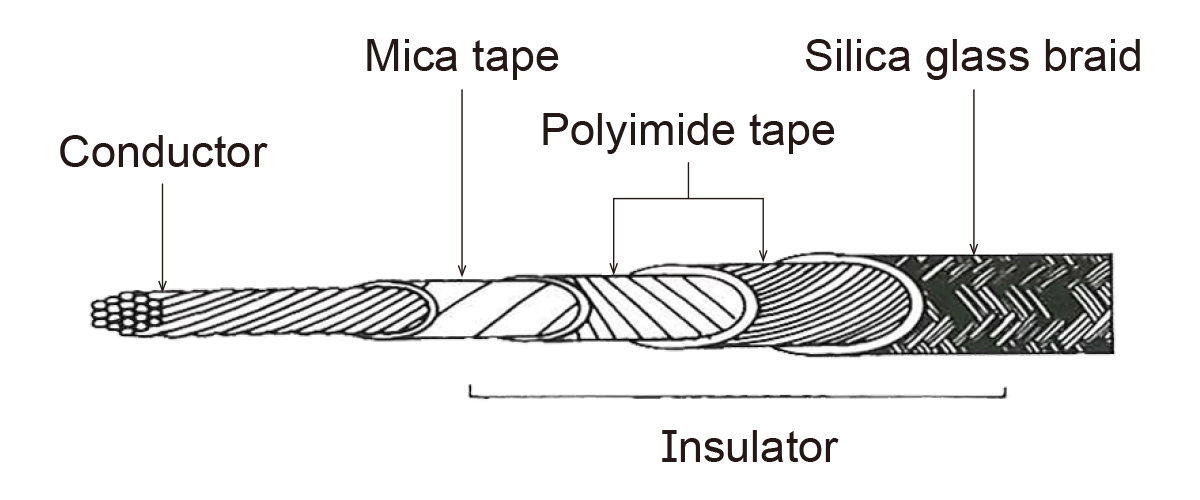

MKT wire

External view

Specifications

| Conductor | Pure nickel wire |

|---|---|

| Insulator | Mica double winding Polyimide tape Silica glass winding braid |

| Safe operating temperature | 400°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Insulator thickness | Braid thickness | Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||||

| 0.75mm2 | 30/0.18mm | 1.1mm | 0.55mm | 0.25mm | 2.7mm | 120Ω/km | 10MΩ/km | 2000V/min | 2A |

| 1.25mm2 | 50/0.18mm | 1.5mm | 0.55mm | 0.35mm | 3.3mm | 72Ω/km | 10MΩ/km | 2000V/min | 3.4A |

| 2mm2 | 37/0.26mm | 1.8mm | 0.55mm | 0.35mm | 3.6mm | 45Ω/km | 10MΩ/km | 2000V/min | 5.7A |

| 3.5mm2 | 45/0.32mm | 2.5mm | 0.55mm | 0.45mm | 4.5mm | 25.7Ω/km | 10MΩ/km | 2000V/min | 10A |

| 5.5mm2 | 35/0.45mm | 3.1mm | 0.55mm | 0.5mm | 5.2mm | 16.4Ω/km | 10MΩ/km | 2000V/min | 15A |

| 8.0mm2 | 7/7/0.45mm | 3.7mm | 0.55mm | 0.5mm | 5.8mm | 11.3Ω/km | 10MΩ/km | 2000V/min | 22A |

The allowable current is a reference value of nickel wire (up to 400°C). It varies depending on the operating conditions. For details, contact our sales representative.

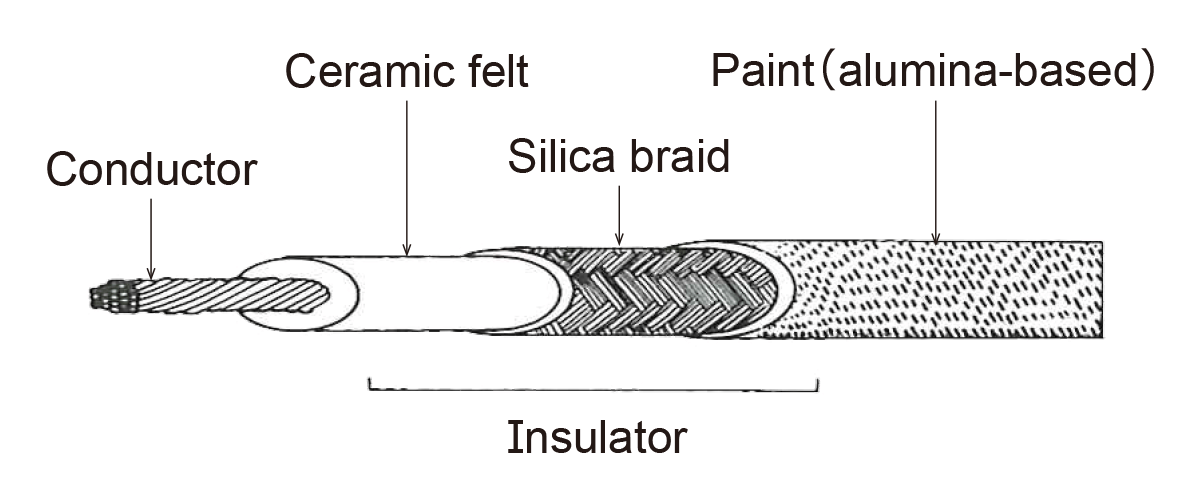

CF wire

External view

Specifications

| Conductor | Nickel plated copper wire (28NPC) |

|---|---|

| Insulator | Ceramic felt Silica yarn Alumina-based paint |

| Safe operating temperature | 400°C |

We have a lineup of the above types of heat-resistant electric wires. Select according to the application, conditions of use, etc.

Heat-resistant electric wires other than the above are also available.

Standard Product

| Conductor configuration | Outer diameter (approx.) |

Standard finished outer diameter (approx.) |

Conductor resistance (Standard: 20°C) | Insulation resistance (Minimum: 20°C) | Test voltage (AC) | Allowable current | |

|---|---|---|---|---|---|---|---|

| Cross-sectional area | Number/strand diameter | ||||||

| 0.3mm2 | 12/0.18mm | 0.7mm | 1.8mm±15% | 74Ω/km | 1MΩ/km | 1000V/min | 2.4A |

| 0.5mm2 | 20/0.18mm | 0.9mm | 2.2mm±15% | 44.4Ω/km | 1MΩ/km | 1000V/min | 4.2A |

| 0.75mm2 | 30/0.18mm | 1.1mm | 2.4mm±15% | 29.6Ω/km | 1MΩ/km | 1000V/min | 6A |

| 1.25mm2 | 50/0.18mm | 1.5mm | 2.8mm±15% | 17.8Ω/km | 1MΩ/km | 1000V/min | 10A |

| 2mm2 | 37/0.26mm | 1.8mm | 3.3mm±15% | 11.1Ω/km | 1MΩ/km | 1000V/min | 16A |

| 3.5mm2 | 66/0.26mm | 2.4mm | 4.1mm±15% | 6.3Ω/km | 1MΩ/km | 1000V/min | 27A |

The allowable current is a reference value of nickel plated copper wire (28NPC) (up to 400°C). It varies depending on the operating conditions. For details, contact our sales representative.

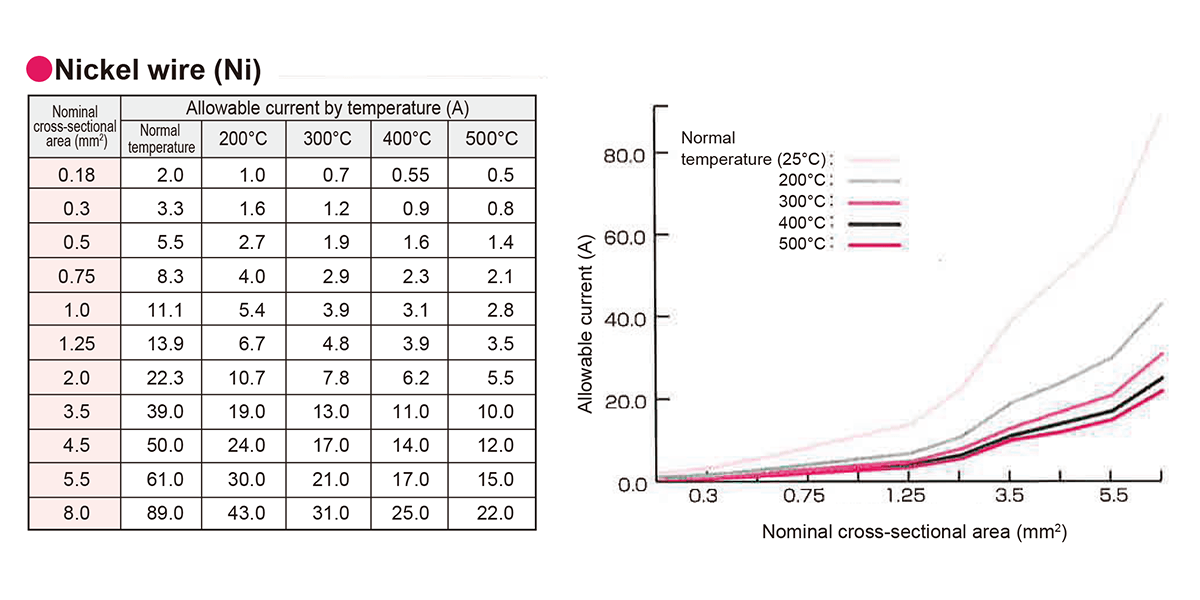

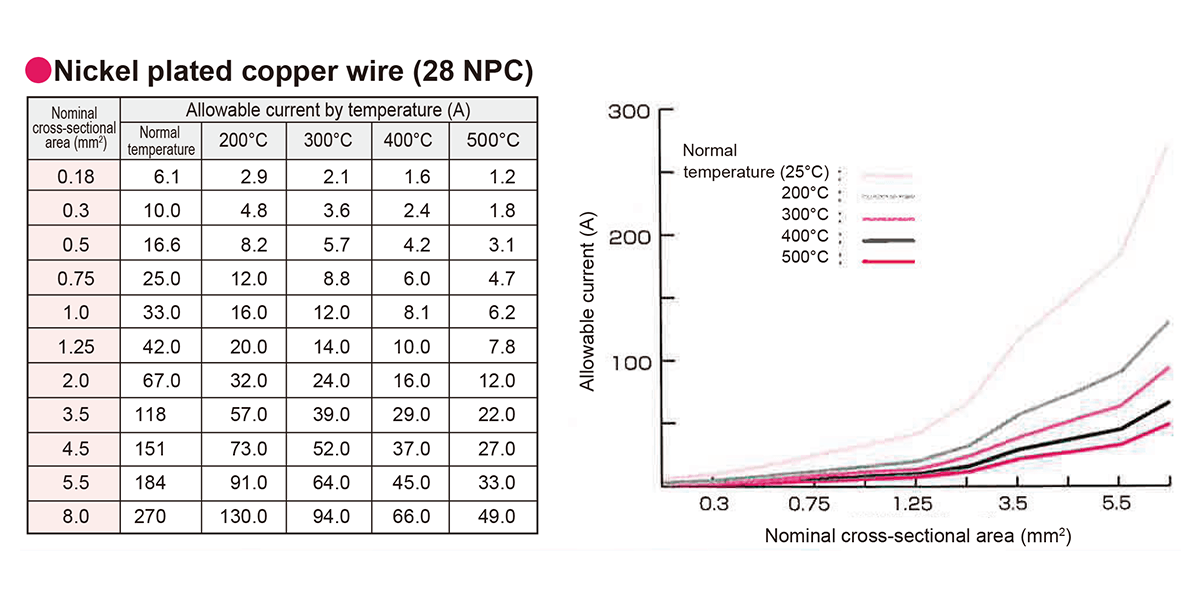

Reference material

Allowable current value of heat-resistant electric wire

- Allowable current value of heat-resistant wire varies depending on the usage conditions.

Especially when using nickel wire, select a wire diameter with sufficient margin because the conductor generates much self heat. - When selecting a heat-resistant cable, ensure that the target quality performance and product safety have been achieved.

- When converging wires in the same pipe, note that the current value may decrease as the temperature rises.

The table below lists reference values based on actual measurement results of the conductor resistance of nickel wire and nickel plated copper wire (28 NPC).

Precautions for use

If you wish to use under the following conditions, please consult our sales representative.

- Do not use products in locations where they are exposed to water or humidity. It may cause an electric shock, electric

leakage, short circuit, or fire.

Braid insulation and winding insulation by glass fiber, silica glass fiber, or ceramic fiber are not a waterproof structure. - Do not use products with overcurrent. It could result in an electric leakage or fire. Use products with a safe current considering the usage method.

Flowing the same electric current in an electric wire with soft copper as a conductor in heat-resistant electric wires using high-resistance conductors such as nickel, nickel braided copper, titanium, etc., will cause overcurrent, possibly causing an electric leakage or fire.

If smoke is generated from the insulator or you sense an odor, stop using the product immediately. Continuing to use it as is could result in an electric leakage or fire. - Do not use it by repeatedly bending, twisting, pulling, wearing, and receiving vibration.

It may cause wire breakage or insulation deterioration. - Do not touch the electric wire during use, nor bring it into contact with parts and equipment. It may cause burns, or damage the parts and equipment. Depending on the value of the current used or the ambient temperature, the electric wire may generate considerable heat.

Therefore, there is a risk of burns if part of the human body touches it, and there is also a risk of damaging heat-sensitive parts and equipment.