Features

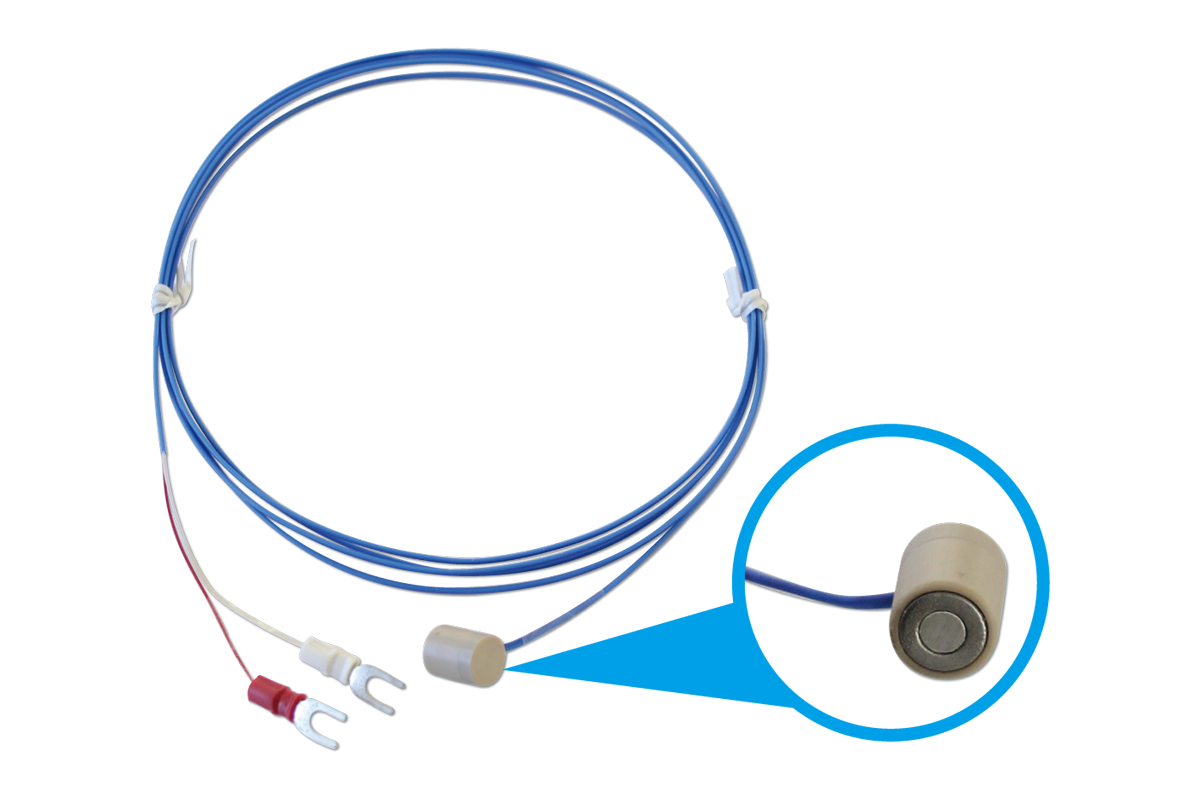

- The magnetic sensor is a temperature sensor for surface temperature measurement that incorporates a magnet into the measuring contact part of a thermocouple or resistance thermometer.

- The magnet mounting method makes it easy to attach and detach the sensor from the measuring object, thereby improving work efficiency.

Specification

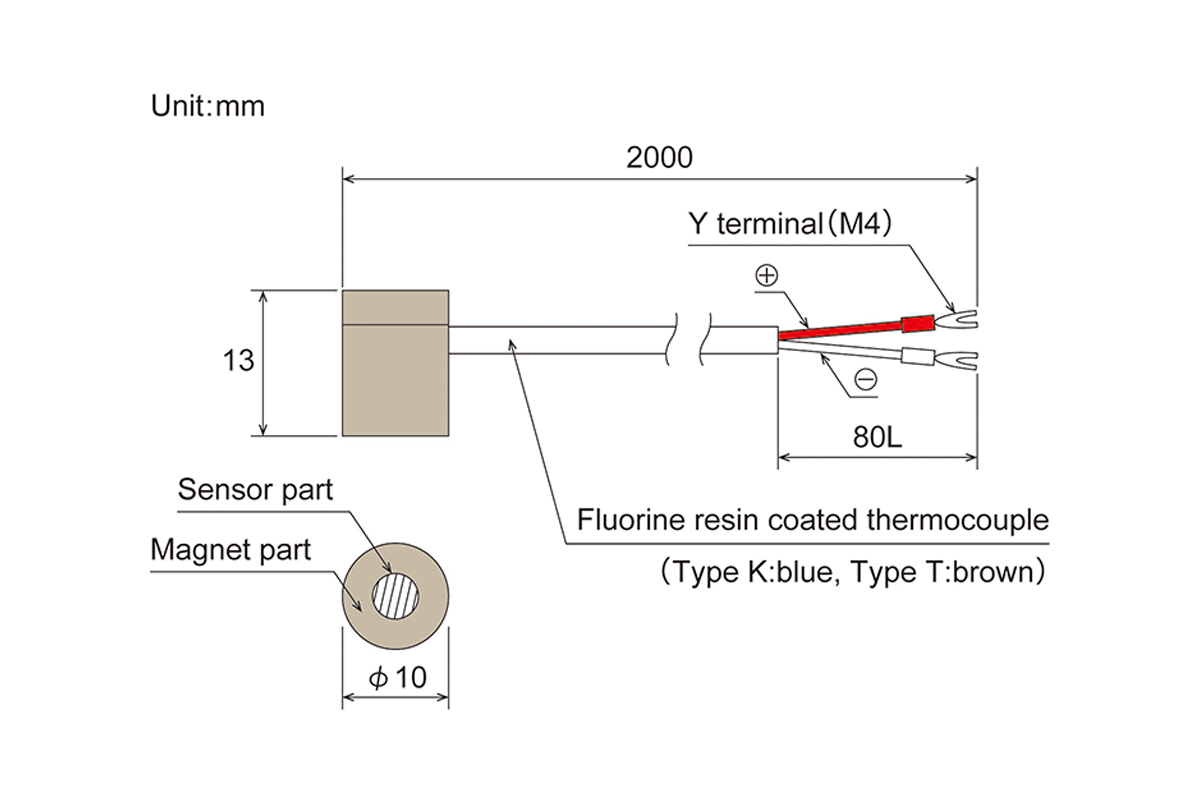

Thermocouple magnet sensor, Horizontal type

| Tolerance class | JIS class 2 |

|---|---|

| Measured temp | Max. 200℃ |

| Meas temp contact point | Grounded |

| Case material | PEEK |

| Connected extension wire | 2 m with fluorine resin coated thermocouple |

| Responsivity | On the Steel plate/110mm x 110mm x t 10 at 100℃ time required for the sensor to reach 90%: approx. 60 sec. time required for the sensor to reach 80%: approx. 30 sec. |

| Sheath material | inconel |

| Product code | Thermocouple Type K(Blue) :MGTCK Thermocouple Type T(Brown) :MGTCT |

*The measured temperature varies depending on the usage conditions and the atmosphere in which the thermocouple is used.

*Can be manufactured with J-type thermocouples.

*Can be manufactured with ungrounded temperature measuring contacts.

*Can be manufactured with the lead wire coming out of the top.

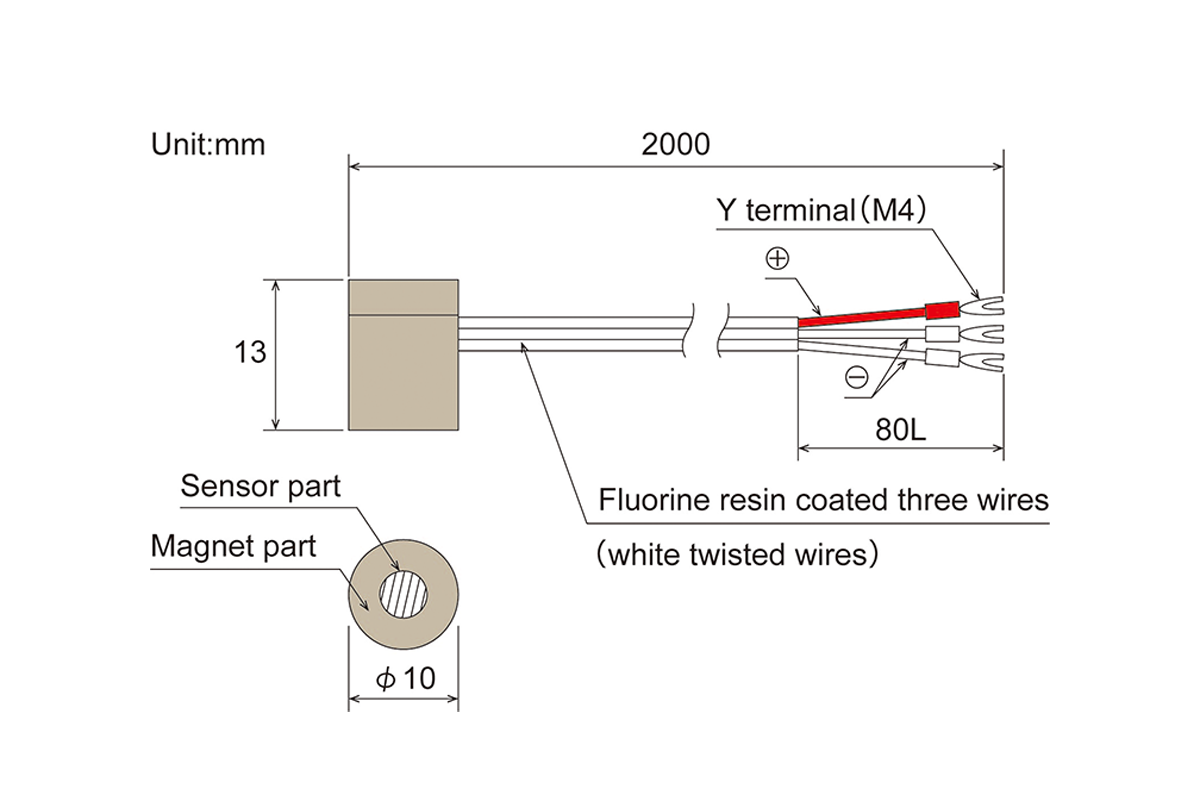

Resistance thermometer magnet sensor, horizontal type

| Tolerance class | JIS class B |

|---|---|

| Measured temp | Max. 200℃ |

| Resistance element | Pt 100 Ω (100 Ω at 0℃) |

| Specified current | 1 mA |

| Case material | PEEK |

| Connected extension wire | 2 m with fluorine resin coated three wires |

| Responsivity | On the Steel plate/110mm x 110mm x t 10 at 100℃ time required for the sensor to reach 90%: approx. 70 sec. time required for the sensor to reach 80%: approx. 40 sec. |

| Product code | 3-wire type:MGPT100 |

*The measured temperature varies depending on the usage conditions and the atmosphere in which the thermocouple is used.

*Can be manufactured with the lead wire coming out of the top.

Precautions when using this product

- The surface to be measured should be free of inclusions that interfere with heat transfer, such as oxide film or scale adhesion.

- Deformation, damage, or contamination of the contacting parts of the sensor will increase the measurement error.

- As with all contact thermometers, there are electrical and thermal errors. It should be measured and evaluated in a separate system before use to quantitatively control the error.

- We recommend calibration every six months to a year, as dirt and other factors can easily cause temperature errors.

- Calibration requires a separate calibration fee.